Top Guidelines Of PLASTIC CNC UP-CUT SPIRAL 'O' FLUTE ROUTER BITS

Our CNC Plastics Diaries

So what materials can be utilized for plastic CNC machining parts? Here are some typical machining plastics: PEEK CNC machining is one facet of plastic manufacturing that uses PEEK product to form pasts. PEEK is a high-performance thermoplastic that has excellent machining properties and can withstand chemical changes much better than the majority of other plastics.

Nylon is typically utilized for CNC plastic machining due to the fact that it can endure wear and tear and doesn't respond poorly to oil and fuel. You Can Try This Source is the shorthand name for acetal resins that are semi-crystalline thermoplastic polymers. When it comes to plastic CNC machining parts, Delrin is a popular choice since it can produce stiff parts, has low friction, and has high dimensional stability.

Plastics' flexibility and numerous benefits make them some of the most essential engineering materials today. BMW saved as much as 100 kg in weight after dropping metals and relying on thermoplastics and composites for the rear boot lid and front wings of its 6-Series Coupe. Without a doubt, BMW could not have actually taken this strong action without ever constructing models and performing tests on them.

Carving Out a Niche in CNC Plastics Machining for Beginners

You should continue to produce plastic prototypes utilizing any machining approach, right? Wrong! BMW may not tell you, however your task's success still mostly depends on the machining approach you use to produce these parts and the third-party producer you choose. This post covers various techniques for creating plastic prototypes, particularly CNC machining.

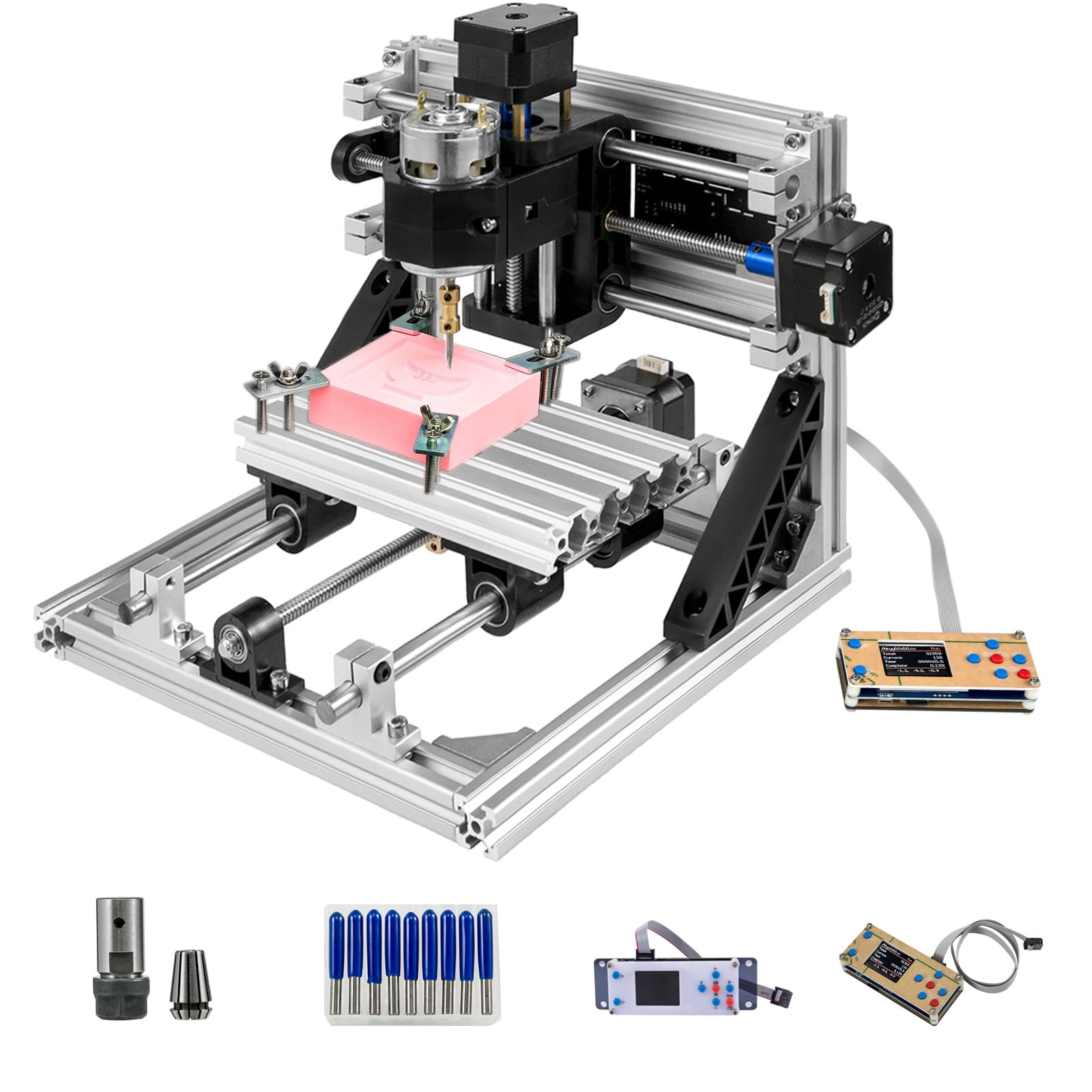

Why Would You CNC Maker Your Plastic Prototypes?CNC machining has various advantages, and here are four circumstances that would necessitate CNC plastic machining. Situation No 1: Your Plastic Model Design Includes Tiny Particulars, Do you have a style that includes patterns with small radii and requires tight tolerances? Then CNC machining is most likely well-suited for your task. 05 mm and tolerances as tight as 4 m. Circumstance No 2: You Required a High-Quality Surface Area End Up, If you're trying to fabricate plastic prototypes solely to picture concepts or ideas, you ought to think about CNC machining. It provides a high-quality surface area finish and doesn't leave layer marks common in the 3D printing process. It encompasses a handful of various technologies-Fused Deposition Modeling (FDM), Stereolithography.

UNDER MAINTENANCE